Eagle Foundry

| Place type: | Industrial building |

|---|---|

| Also known as: | Eagle Foundry B&B |

| Address: | 23-25 King Street |

| Town or Locality: | Gawler |

| Year constructed: | c. 1870 |

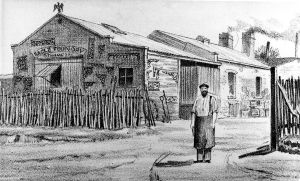

| Built by: | David Thomson |

Eagle Foundry History

The man who started the Eagle Foundry in 1870 was David Thomson. He was born at Renfrey in Scotland on October 3rd 1820. He married Elizabeth Currie from Glasgow and they had 3 sons born in Scotland… they were Alexander, Daniel and David. The family decided to leave Scotland and travel to Australia, David Thomson was 32 years of age at the time. So, on the 26th of December 1852, David and Elizabeth Thomson and their 3 sons, Alexander, Daniel and David boarded the ship the MARSHALL BENNETT and left from the port of Plymouth in South West England. One man and 7 children died at sea on that voyage and unfortunately David’s son, Alexander, was one of the children who died. David Thomson was a blacksmith, moulder, ironfounder, and engineer.

He arrived in South Australia on April 28th 1853 and worked for a short time in Adelaide with a Mr Pybus as an ironfounder. He then went to the Victorian diggings in 1854 and returned to Adelaide in 1855. In 1856 he started working at James Martins Phoenix Foundry and subsequently became the forman of the moulding team. He worked at the Phoenix Foundry for fourteen years.

In 1870 David Thomson launched out on his own and established the Eagle Foundry on King Street in Gawler. David did not have an abundance of capital but he possessed three qualities, determination, sound judgement and perseverance. He chose the site because of its proximity to good moulding sand in the nearby Gawler River. In the course of time the Eagle Foundry was known for items like plough shares, garden seats, balustrading, troughs, verandah columns, freeze work and grave surrounds, etc. As with most other foundries, plough shares were made in large numbers to suit most types of plough mould board foot designs. They were cast in cast iron dies and the Eagle Foundry produced approximately 20,000 per annum. Mr Thomson had up to 30 men working for him at the Eagle Foundry and there was never an industrial dispute or strike while he was in charge.

David Thomson was a man of few words but his actions spoke more than his words and his was an upright and honorable man and was well respected in the community. David and Elizabeth Thomson had 10 children altogether, 3 being born in Scotland and 7 born in South Australia. David Thomson died on January 22nd 1903 aged 82. He was survived by his widow Elizabeth, five sons, Daniel Thomson, David Thomson, Robert King Thomson, James Jack Thomson of Gawler, Mr. J. A. Thomson of Angaston and two daughters Mrs. M. Wilson of Prospect and Miss Thomson of Gawler.

After David’s death the business was continued by his sons, Daniel, David, Robert King and James Jack Thomson. James Jack Thomson gradually purchased the shares of the other partners until he became the sole proprietor and remained so. James Jack Thomson or Jimmy Thomson as he was known, was the first Gawler player to appear in inter colonial football and was a member of two Norwood premiership teams. He was a talented all round sportsman and showed great early promise as a follower in three seasons with Gawler when it was a member of the SA Football Association and was vice-captain in 1888. Jimmy married Isobel Bews in 1899 and joined the Eagle Foundry, which was a family business founded in Gawler by his father David who campaigned for the eight-hour day as a young Scottish immigrant and was a union member for 65 years even as an employer. Jimmy was the last of the four brothers to run the business. He died at the age of 77 on 15 November 1944.

This was just after the return of the foundry's cast iron eagle mascot, which high-spirited airmen had taken to New Guinea early in World War II. It was presented to the people of Gawler by members of 86 Squadron RAAF in memory of local flier, Pilot Officer Ivor Hatcher who was killed in action in the South West Pacific.

After Jimmy’s death in 1944 his son Hugh Gordon Thomson, returned from war service with the Australian Imperial Forces and took over the management of the business. By this time the amount of work passing through the foundry had reduced and only 2 or 3 moulders were employed. Hugh Gordon Thomson was known as just Gordon and his wife Ruth,(after 1946), did all the office work for the business. Ruth Thomson was a remarkable woman, who put on overalls on cast days and assisted in the pouring operations, she skimmed the slag from the ladles of molten cast iron and shifted the weights used to hold down the moulding boxes while the metal was entering the mould. She delivered castings in the firms truck, often commencing at 5.00am to drive to Hahndorf, then on to the gasworks at Brompton to pick up a load of coke to fire the furnaces.

In 1955 Gordon Thomson was badly burned in a foundry accident and on returning to the works some months later, looked after the machine shop and ran the Shearer agency.

The foundry ceased operating in 1964 and Hugh Gordon Thomson died on the 18th of March 1972. After Gordon died, his widow Ruth, auctioned the property but it was passed in, as the property didn’t meet the reserve price. Ruth was worried the property would be demolished by developers and an agreement was reached to sell the property to Geoff and Liz New who purchased it in November 1972 under the condition they wouldn’t demolish it. Geoff’s plan was to establish an arts and crafts centre in Gawler.

The next phase in the life of the Eagle Foundry was in the hands of Geoff New who described himself as a teacher, an artist and a conservationist.

The following is an extract from Liz New who remembers some of the work that was done at the Eagle Foundry.

The galvanized iron buildings at the front of the block were removed and replaced with the brick structure that is now called the Thomson suite. Ruth Thomson donated the magnificent Lead Light Eagle stained glass window that was made by Adelaide stained glass artist, Franz Kat, as her gift to the project.

Ruth Thomson then moved from her cottage in King Street to Plympton, but would call in to the Foundry on her visits to Gawler. She gave Geoff and Liz a copy of the film “Mr Thomson Remembers” which they donated to the Town of Gawler.

Over the following years various classes and workshops were held, some subjects being leadlight, pottery, painting and life drawing. Art materials were sold and art works were available for purchase at the gallery.

Terry Beaston, stained glass artist based at Brighton and Viv Rush, were two artists who held classes at the Foundry. Julia Mannix conducted some pottery classes when she first arrived in Gawler from the UK. A blacksmith, John Ailmore, conducted his trade from the blacksmiths shop at the rear of the Foundry. A carpenter spent some time making kitchen dressers and several potters worked there. Two live-in workshops were conducted by hot-glass artists who came from America with the assistance of Arts Council grants. The first was Paul Marioni from Seattle and later David Ruth from California. These workshops were organized by Geoff New and Terry Beaston.

Hot glass artists came from all over Australia to take part in the workshops, staying at the Foundry, bunkering down in various nooks and crannies. These were very interesting years.

The Foundry was sold in 1989, so the News owned the foundry for 17 years. The next chapter in the life of the Eagle Foundry was about to commence.

The following extract is based on Christine Spencer’s recount of her years at the Eagle Foundry.

In 1988 John and Christine Spencer were married and were looking for a home to settle in. They were looking around Gawler and stumbled across the Eagle Foundry. They had a sneak peek at the ruins of the Foundry.

They both fell in love with the dream of what it could be. John was a creative carpenter, with grit, focus and determination. Christine had the vision of wanting to create a welcoming home space, with freedom to move and grow with the history and remnants of a foundry. On the 2nd of February 1989 Chris and John purchased the Eagle Foundry.

When they arrived….. there were the main brick large rooms that Geoff and Liz had created. These were used for pottery and art workshops in the past. When Christine and John moved in, the foundry had been disused for some time and there was evidence of squatters living there.

The main goal for them was safety and security. They loved the spaciousness of the foundry and with the help of family and friends, things started to take shape.

Christines father was a bricklayer and helped to secure the walls that were half there and falling.

Christine and Johns 2 daughters were born whilst living at the Eagle Foundry.

There was always a constant flow of people knocking on the doors, either relatives, or people interested in the history. There was also busses stopping outside on a history tour with a local historian.

It took John and Christine a while to decide what to do with the Eagle Foundry. The Bunyip had suggested there was a lack of accommodation in Gawler and as John was working on B&B’s in the Barossa and the 3 day horse event was calling out for accommodation, they began creating a suite for visitors. In 1994 they had their first guests.

Apart from accommodation they had art exhibitions, community meetings, breakfasts, school tours, weddings and a few receptions.

By the time the family left the Foundry the business was going well and the reason for leaving was so they could be more involved and present with their daughters’ high school years.

The Spencers were there at the Eagle Foundry for 13 years, it was a labour of love, friends and hard yakka.

They met Ruth Thomson numerous times and described her as a beautiful lady that enjoyed spending time with Christine and reminiscing.

In 2002 Christine and John Spencer sold the Eagle Foundry to the Iremonger family.

Leonie and Gary had just 6 months before sold their 4 bedroom, 10 acre property at Gawler Belt and moved into a small renovated cottage in Jacob Street. The neighbours said we will give you 6 months and you will leave, as going from a 4 bedroom home on 10 acres to a 2 bedroom cottage is too much of a downsize.

Well their daughter Kimberly wanted to come back to Adelaide from Melbourne and when they all went to check out the Eagle Foundry they just fell in love with it and decided to try and get finance to purchase it. So in August 2002 they all moved in, Leonie, Gary and daughters Kimberly and Veronica

They decided to take on the accommodation business as well to supplement the bank repayments. At first they started the business on a part time basis as Leonie was working full time at the Gawler Post Office and Gary was a full time sales rep. They took bookings and left keys under door mats for incoming guests and stayed in a few B&B’s themselves so they knew what guests expected.

There was a lot of maintenance to be done at the Eagle Foundry and it took up a lot of weekend time as well as us cleaning the suites after guests left. There were also upgrades to the electrical switchboards, tiling to the floor in the bridal suite, cleaning the leaves etc from the driveway and cutting the lawns.

It was a labour of love and in the early days they were fortunate to have guests from the TV series McLeods Daughters stay with them, which helped make ends meet.

To get more bookings and to promote the Eagle Foundry B&B they had open days where we would have a harpist play music in the courtyard and have potential visitors view the suites.

They also partnered up with a lady called Jacquie Law Smith who promoted the Eagle Foundry B&B by having the Foundry participate in the Gawler Gourmet and Heritage Festivals that ran from 2004 to 2008.

After the Global Financial Crisis hit in 2008 Gary focused more time in running the B&B and so in that year he started full time at the Eagle Foundry.

There were still a lot of areas at the Eagle Foundry that needed upgrading and so they took a chance in 2011 and arranged an architect to draw up plans for them to turn the old run down Blacksmiths shop into 2 new accommodation suites.

It took around 12 months for the plans to be approved but after the approval, there wasn’t any money to finish the job. Also, there were 3 heritage walls that needed repairing and so Gary set about doing repair work on them himself whenever time permitted.

Leonie gave up work at the Post Office in 2012 and worked full time with Gary on the jobs at the Eagle Foundry.

It was around May 2014 and they had already had approval in 2012 to put in the new accommodation suites so Gary thought it’s time to start to demolish the old tin shed that was the original blacksmiths workshop and get on with the renovations. He had been working on repairing the walls and so he thought the walls should be able to withstand the demolition now. He attached a rope to his car and just pulled the walls and roof down. Then took all the rubbish to the dump.

They decided to at least get the slab down and think about how they would fund the rest of the project later and so they organized contractors to lay the slab.

There was still a lot of promotion to get people to come to the Eagle Foundry (even while the work out the back was being done) and so after joining the Gawler Business Development Board the family set about creating a Jazz festival to entice visitors to the town and promote the Foundry.

The Jazz Festival ran from 2013 to 2017.

After a while they decided to slowly purchase some Hebel blocks for the walls for the new suites and finally found a bricklayer to lay them.

Slowly they found money to put the roof on, start work on the internal frames, get the electrical and plumbing work done then the flooring, second fix, tiling, put the carport on and then do the cladding on the outside and then the stormwater and the pavers.

Eventually after several years the Blacksmith suites were finished. It took from 2011 to 2017 to get the job finished.

In 2019 they upgraded the old Bridal Suite by adding on a new more modern bathroom. This enabled guests to have more room in the suite and have a king bed installed. They changed the name to the Foundry Suite and improved the kitchen area.

In December 2018 Eagle Foundry B&B went from a 3.5 star rated property to a 4 Star rating from the SA Tourism Council of SA. In 2020 they managed to top this and it’s now rated as a 4.5 star accommodation provider.

Eagle Foundry has been a work in progress right from its existence.

The Thomsons added to the foundry for 3 generations, Geoff and Liz New added their bit of history to the structure.

John and Christine Spencer continued to improve the Eagle Foundry and turned it into a functional business.

Leonie and Gary Iremonger have also left their mark there.

There is still more work to be done at the Eagle Foundry and Gary hopes to continually improve the Eagle Foundry so future generations can enjoy what David Thomson started in 1870.

The patterns for the detailed frieze work were made for the foundry by carving the design in lead or plaster of paris. No other mention is made of patternmaking facilities or machinery.

Ruth Thomson, widow of Hugh Gordon Thomson (known as Gordon), has said that as far as she can remember no patterns were made at the foundry. The foundry initially concentrated on the production of castings but machining facilities were added at a later date.

David Thomson died on January 22nd 1903 aged 82 and the business was continued by his sons, Daniel, David, Robert King and James Jack Thomson. David Thomson also had 3 other sons, Andrew, aged 2 when he died, Alexander aged 4 when he died and John, aged 2 when he died. There was also a daughter called Ellen who was born on 12-8-1854 and died on 4-10-1935. Davis Thomson’s wife, Elizabeth Thomson (nee Currie) passed away on May 2nd 1920 aged 92.

James Jack Thomson gradually purchased the shares of the other partners until he became the sole proprietor and remained so until he died in 1944. His son Hugh Gordon, returned in 1945 from war service with the A.I.F. and took over the management of the business.

By this time the amount of work passing through the foundry had reduced and only 2 or 3 moulders were employed. Some of the customers for castings were Kaesler Brothers of Hahndorf, the Woods and Forest Department, Hallett Brick Co and numerous bakeries. The foundry and machine shop catered mainly for spare parts for machinery which had been out of production for some time and replacement parts had to be manufactured. Pig troughs were also a steady product for this foundry.

Ruth Thomson, recalled the activities of the foundry during the years after world war 11 and remembers seeing the ‘four seasons’ seat being cast in the foundry but only a small number of people could afford them because of the increasing cost. When the foundry finally closed Mrs Thomson donated the patterns to the Gawler National Trust who had them put together as a seat.

After 1946 Ruth Thomson did all the office work for the business. This remarkable woman also put on overalls on cast days and assisted in the pouring operations, skimming the slag from the ladles of molten cast iron and shifting the weights used to hold down the moulding boxes while the metal was entering the mould. She delivered castings in the firms truck, often commencing at 5.00am to drive to Hahndorf, then on to the gasworks at Brompton to pick up a load of coke.

In 1952 Frank Burnett commenced his apprenticeship as a moulder at Eagle Foundry and was the last apprentice to serve his time there, finishing in 1956.

In 1955 Gordon Thomson was badly burned in a foundry accident and on returning to the works some months later, looked after the machine shop and ran the Shearer agency.

The foundry ceased operating in 1964 and the property was sold in November 1972.

According to John Clift, David Thomson settled in Gawler in 1856 and worked as a moulder in James Martin's foundry.

The Eagle Foundry is mentioned on document pages 97-102 in "Gawler’s Industrial Buildings 1839 – 1939” by Susan Phillips and Michael Pilkington

Please click here for photos of Eagle Foundry.

D. Thomson Eagle Foundry – Bunyip 17May 1878

JOTTINGS IN AND AROUND GAWLER.

(BY ROUNDABOUT.)

'A chiel's among ye takin' notes,

An faith he'll prent 'em.' — BURNS

“Again back from the realms of reverie and imagination I resume my 'Jottings,' feeling assured that the interesting works now about to be described will merit public attention. Colonial manufactures are still in their infancy, but they are rapidly extending, and must eventually be widely known and appreciated. My first enquiry is, whenever, I see an engine or machine of any kind. 'Is it colonial made ?' and there is a sort of satisfaction to learn that it is not only colonial made, but of local work manship.

Some splendid work has been turned out at the EAGLE FOUNDRY, which, under the supervision of its spirited poprietor, Mr D. Thomson, and his enetrprising sons, reflects the highest credit on their skill and ingenuity. A description of the work which I have this week visited may not be out of place. The Foundry is situated in King-street, within sight of the Park Lands, of which it commands an extensive view. The work performed here comprises casting of various kinds, principally for building, balus trading, balcony pannels, garden seats, wheels, saw plates, ploughshares, pig and horse troughs, and other articles of a like kind.

Entering the premises we were shown several of these of the most elegant description. The visitor is particularly struck with the novelties presented to him, and it is hard to understand how such beautiful and recherche designs can be brought out so perfectly in iron. The art and mystery of the whole was, however, explained, and I must confess its simplicity and the ease with which it was performed quite astonished me. At the time of my visit a blast was about to be put in and a casting to take place. Of this, as I was eye-witness, a description is given at the end of this paper.

The first object to which attention is directed is the raw iron, which is in pigs weighing 1 cwt. each. These are imported from England, and are considered of excellent quality, and of which, when broken, their appearance afforded ample testimony. I learn there is plenty of iron ore in South Australia, and that experiments made in relation to it prove its utility and adaptability for manufactures. The cost of bringing it to perfection from its crude state is however too expensive, and from the absence of coal here a sufficient deterrent to prevent its being used for some time to come. When South Australian coalfields are an established fact we shall be able to bring our manufactures more prominently forward than at present. After being broken into small pieces the iron is taken to the furnace, cast in, and speedily under the severe heat to which it is subjected reduced to a molten state.

Entering the Dressing Shop, the engine, which is a compact 6-horse power machine, having all the latest improvements, and with a large boiler by Hooper, of Adelaide, meets, the view. Its uses are manifold, but the principal is the driving of a fan to send the wind into the furnaces. A blacking mill is also another very noticeable object here. Charcoal finely powderel is shaken on it, and this gives the castings a fine polish. A black smith's forge with all necessary appliances for working is noticeable, as also are some ballusters and ornamental railings made by the firm and set up in this compartment.

The Lathe Room was the next place visited. As implied by its name it contains the lathe which is driven by the engine. Its chief uses are the screwing of bolts, and both screwing and drilling are combined by its means. Most of the fancy work turned out here goes to Adelaide, and the hands are kept constantly busy in executing orders for that locality alone. Ascending a flight of steps on the outside we reached the furnaces, the charging holes of which are placed on the top of the establish ment. The furnaces are said to be 2 feet 6 inches in diameter, and about 12 feet deep from the charging holes. The force and power of the fire would perhaps be hard to estimate, but the sight of this fierce body of seething incandescent flames thrusting out their forked tongues as if in search of prey is a sight not easily forgotten by the beholder. A charge for casting comprises 2 cwt. of iron to 1 cwt. of coke, and five tons of casting can be manufactured at one time from one furnace, and three tons from another. The coke used comes from Queensland, and is considered an excellent article, superior even to that obtained from Newcastle and other notable coal-bearing centres. Gawler coke is also used, but as it possesses less heat-giving qualities is not in request. The rapidity with which the iron melts is astonishing, a few minutes usually sufficing to render it malleable, and one man is kept pretty busy in supplying the furnaces with this sort of fuel.

Descending the staircase we were conducted to the mouth of the furnaces, from which the molten iron of bright red color, and fluid as water was being taken in small iron buckets fixed to long-handled poles. Fancy castings were about to be made, and the pro cess which would take too long to depict was satisfactorily explained. Ploughshares and scarifiers were also being manufactured, and the celerity wiih which a few dozen of them was turned out was surprising. These are in demand by the farmers, and it is estimated that not less than 1,700 dozen are made during the season. The moulds for the castings are of various shapes and forms, and no matter how intricate the design it can be formed here; in fact some of the fancy work executed at this establishment has never been surpassed. Some very pretty garden seats, representing the four Seasons, similar to those exhibited by Messrs Thomson & Sons at the Agricultural Society's Show at Gawler during the present year were shown me, and clearly evidenced the perfection to which the working of iron has been brought in the present century.

The operation of casting is calculated to interest, and impress the visitor. The moulds are of castiron, well plugged with clay, two holes being left by the cores in each, and into these the molten metal is poured. A dense smoke arises as this is performed, and one can easily picture what effects might be produce if the boiling iron were capsized on the human subject, or accidentally spilled on some combustible surface. All here is however safe, and invulnerable to its effects, the workmen pursue their somewhat phoenix-like occupation with alacrity, and all goes on satisfactorily. The cores with which the holes in the castings are made are constructed by boys from sand, and are hardened ready for use in a small stove. Thongh there is plenty of fire used almost daily in the establishment, there is little danger of any conflagration taking place, and although, as has been shown, iron will burn, it must indeed be a super-strong heat to cause it to do so. There is no lack of water here, a well 75 feet deep supplies the engine by a force-pump, and there are also tanks on the premises capable of holding altogether about 1,600 gallons.

Among noticeable objects in this part of the works is a rope column design in iron; it is useful either for verandah posts or balconies, brackets of various kinds, castings for seed sowers, (of which tbe firm have just executed an order for Adelaide), and a large crane, the lifting capacities of which are estimated at between 4 and 5 tons, and which raises heavy moulds which cannot be easily lifted by hand were shewn, and their several uses explained. It may be here mentioned that the design from which the work is modelled are first cut in plaistex of Paris or lead, which may thus be termed preliminaries to casting. The brass furnace was the last object visited, it is in appearance no speciality, but is nevertheless very useful to such an establish ment. By its aid the machine brasses, mill and pump brasses are turned out, together with numberles other articles of a like kind.

About fourteen hands, including boys, are employed, the working hours being 8 hours per diem, or 48 hours per week, unless when work is pressing, and then overtime is paid for. As employees, Mr. Thomson bear an excellent name for their upright and straightforward character, and the most perfect harmony exists between them and their workmen. Farming implements and fancy palisading, whether for fences or graves, would appear their speciality, and they have, since commencing business, executed many larger orders of this kind in a satisfactory manner. As a rule, machinery and manufactories do not possess that amount of interest which other subjects not so important may do, but I must say that my visit to the Eagle Foundry was attended with pleasure and profit, since thereby I learnt many things of which I was hitherto ignorant. Though I was hardly prepared to go so far as the Cockney who imagined that 'loaves of bread grew on trees,' I was nevertheless quite in the dark as to the manner in which many beautiful articles in iron work were made. Some of our Gawler residents are possibly unaware of the wonders of casting, and they will therefore do well to act as I have done, go some day when there is a 'blast' on and see Messrs. Thomson and Sons at work. They will then be able to judge as to the correctness of the foregoing statements, and be thoroughly enlightened as to much which at present is to them an unfathomable mystery.”

Bob Evers Great great grandson of David Thomson the elder

The Video "Mr Thomson remembers", produced by John Morley, and Directed and filmed by John and Pat Toplis, is available for viewing on the right of this screen.

Click here to read "A Tale of Two Lathes - By Peter Hoye

Please click here to view historical information from the 1998 Danvers Heritage Survey regarding this location. <1>

.

Related Articles

External Links

References

Memories of Eagle Foundry

Do you remember Eagle Foundry ? Then Join up and add your memory here.